REACH

The primary objective of the REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) Regulation (EC) No 1907/2006 is to protect human health and the environment by ensuring greater safety in the production and use of chemical substances.

Authorisation process

Authorisation process risk management of chemical Substances of Very High Concern (SVHC), such as carcinogens, mutagens, and toxic for reproduction chemicals, is done through an authorisation process in three phases:

- identification of SVHC;

- recommendation for inclusion in the Authorisation List; and

- application for authorisation by industry.

The European Chemicals Agency (ECHA), the EU Member States, and the European Commission are involved at various stages during the process, and third parties are consulted at all stages. SVHC that have been included into the Authorisation List can only be used after the 'sunset date' if authorised by the European Commission. One previous example where an authorisation was granted to the aviation industry, due to the absence of alternative chemicals that were fit for this purpose, was in the use of chromium trioxide for surface treatment to prevent corrosion.

Restriction process

Restriction is used as a regulatory risk management tool when a Member State or ECHA, at the request of the European Commission, are concerned that a certain substance or a group of substances pose an unacceptable risk to human health or the environment. Restrictions usually limit or ban the manufacture, placing on the market, or use of a substance, but they may also include specific conditions, such as technical measures, limits, labelling requirements, etc. For chromium, many of these substances are already listed in Annex XIV of the Authorisation List, and are therefore subject to the REACH authorisation regime. However, the number of applications for authorisation has far exceeded the predictions at the time of inclusion of the substances in Annex XIV. This causes delays in the processing and granting of authorisations, but also in the implementation of the risk management measures or conditions set when an authorisation is finally granted. For this reason, a restriction process has been launched.

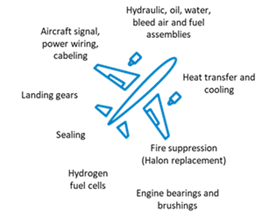

Another example for a restriction process is related to per- and polyfluoroalkyl substances (PFASs), which are synthetic chemicals that resist grease, oil, water, and heat. Due to these properties, they are found in thousands of consumer products from raincoats to frying pans, and are also used to meet safety requirements in modern aircraft. To mitigate the risks of PFASs, five EU Member States prepared a restriction proposal to limit the use of this group of substances, which was submitted to ECHA in 2023. The ECHA scientific committees are currently evaluating the proposal and will issue their opinion to the European Commission in due time. The public consultation of the restriction proposal has led to an unprecedented number of comments, and the evaluation process is therefore expected to last longer than usual for a standard restriction. The impact on aviation will depend on how the restriction will ultimately be implemented by the European Commission.

Figure 1: Non-exhaustive illustration of safety-relevant use of PFASs in aircraft manufacturing

REACH in aviation

REACH poses a number of unique problems to the aviation industry:

-

Complex supply chain

The aviation industry deals with intricate supply chains involving various stakeholders, from manufacturers to suppliers, maintenance providers, and airlines. Coordinating these components efficiently can be challenging.

-

Low volume of chemicals

Due to the relatively low volume of specialised aviation chemicals, compliance can be complex.

-

Long production timelines and complex products

The design, testing, and certification processes are intricate, requiring collaboration among engineers, manufacturers, and regulatory bodies.

-

Highly regulated certification process

Aviation products must undergo rigorous certification processes to ensure safety and compliance. For instance, substances like Chrome VI used in surface treatments require careful handling and adherence to safety standards.

-

Operational longevity

Aircraft are expected to remain operational for decades. Ensuring that materials, components, and systems meet safety requirements throughout their extended lifespan presents a significant challenge; therefore, alternative substances cannot be used without approval.

EASA’s role and collaboration with ECHA

The European Union Aviation Safety Agency (EASA) and the European Chemicals Agency (ECHA) have established a partnership to ensure aviation safety while implementing the REACH Regulation in line with Article 87(2) of the EASA Basic Regulation.

A joint report: An elaboration of key aspects of the authorisation process in the context of aviation industry was published in 2014 by EASA and ECHA to clarify the nature of the REACH process on the one hand and the nature of aircraft certification for airworthiness and environmental protection on the other.

In 2017, EASA and ECHA signed a Cooperation Agreement to exchange critical information as regards the REACH processes and chemicals relevant to aviation.