Regulation (EU) 2022/1358

This Subpart establishes:

(a) the procedure for declaring the compliance of a change to the design of an aircraft which was subject to a declaration made in accordance with Subpart C of this Annex;

(b) the rights and obligations of the declarant making a declaration of compliance of the change referred to in point (a); and

(c) provisions regarding the standard changes that do not require a declaration of design compliance.

ED Decision 2023/013/R

The term ‘change to the design of an aircraft which was subject to a declaration’ is used in Part 21 Light Subpart F, as well as in the related AMC and GM, to refer to any changes to the elements of the aircraft design data as defined in point 21L.A.46. Therefore, a declaration of design compliance should be required for any changes to the aircraft design data defined in point 21L.A.46.

Regulation (EU) 2022/1358

(a) Standard changes are changes to the design of an aircraft which was subject to a declaration made in accordance with Subpart C of this Annex and which:

1. follow the design data included in the certification specifications issued by the Agency, containing the acceptable methods, techniques and practices for carrying out and identifying standard changes, including the associated instructions for continued airworthiness; and

2. are not in conflict with the design data covered by the declaration of aircraft design compliance made in accordance with Subpart C of this Annex.

(b) Points 21L.A.103 to 21L.A.108 are not applicable to standard changes.

GM1 21L.A.102 Standard changes

ED Decision 2023/013/R

APPLICABLE CERTIFICATION SPECIFICATIONS

CS-STAN87https://www.easa.europa.eu/en/certification-specifications/cs-stan-stan… contains the certification specifications referred to in point 21L.A.102(a)(1). Guidance on the implementation of Standard Changes and Standard Repairs may be found in AMC M.A.801 of the AMC to Part‑M.

21L.A.103 Classification of changes to the design of an aircraft for which design compliance has been declared

Regulation (EU) 2022/1358

(a) Changes to the design of an aircraft which was subject to a declaration made in accordance with Subpart C of this Annex shall be classified as minor or major, using the criteria laid down in points 21L.A.63 (b) and (c).

(b) The design compliance of a minor change shall be declared in accordance with point 21L.A.105.

(c) The design compliance of a major change shall be declared in accordance with point 21L.A.107.

GM1 21L.A.103 Classification of changes to the design of an aircraft for which design compliance has been declared

ED Decision 2023/013/R

Major changes that are classified as being ‘substantial’ should require a new declaration of design compliance to be submitted in accordance with Subpart C of Annex Ib (Part 21 Light).

Examples of major changes that are considered substantial may be found in Appendix B to GM1 21L.A.103.

(a) PURPOSE OF CLASSIFICATION

The purpose of the classification of changes to the design of an aircraft that was subject to a declaration made in accordance with point 21L.A.63 of Subpart C is to allow the declarants to determine the route to be followed for the declaration and whether they need to submit the declaration to EASA (major change) or to maintain it in order to make it available to EASA upon request (minor change).

Point 21L.A.63, as referenced by point 21L.A.103(a), requires that all changes be classified as either ‘major’ or ‘minor’ using the criteria in point 21L.A.63.

(b) INTRODUCTION

(1) Point 21L.A.63(b) and (c), as referenced by point 21L.A.103(a), proposes criteria for the classification of design changes as either ‘minor’ or ‘major’.

This GM is intended to provide guidance on the term ‘appreciable effect’ affecting the airworthiness of the product, the declared noise or emissions levels or affecting any of the other characteristics mentioned in point 21L.A.63, where ‘airworthiness’ is interpreted in the context of a product in conformity with the applicable detailed technical specifications and is in condition for safe operation. It provides complementary guidelines to assess a change to the declared aircraft in order to meet the requirements of point 21L.A.103 where classification is the first step of a procedure.

Characteristics affecting the environmental compatibility of the product are characteristics affecting the compliance of the product with the applicable environmental protection requirements.

Note: For classification of repairs, see GM 21L.A.223.

Although this GM provides guidance on the classification of major changes, as opposed to minor changes as defined in point 21L.A.103, the GM and point 21L.A.103 are deemed entirely compatible.

Appendix A to GM1 21L.A.103 provides examples of major changes and a classification process.

(c) ASSESSMENT OF A CHANGE FOR CLASSIFICATION

(1) Changes to the declared design

Point 21L.A.103 addresses all changes to any of the aspects of a declaration of design compliance that was submitted under Subpart C.

(2) Reserved

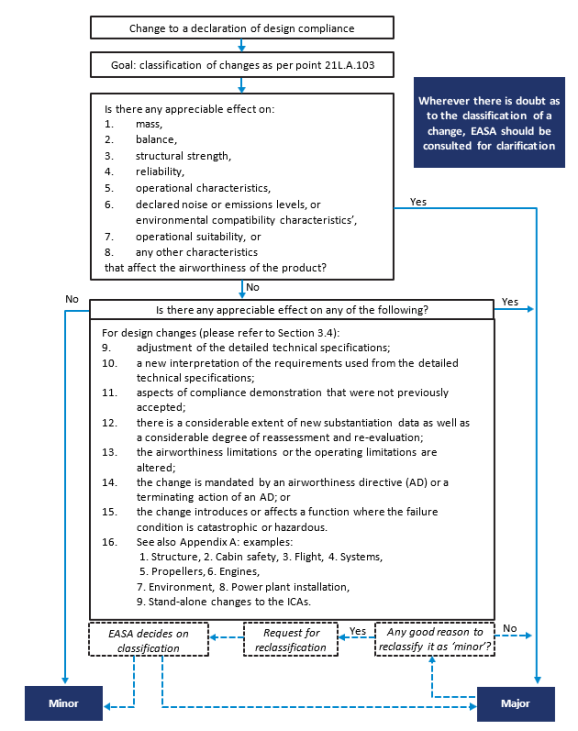

(3) Classification process (see also the flow chart ‘Classification process’ in Appendix A to GM 21L.A.103)

Point 21L.A.103 requires all changes to be classified as either ‘major’ or ‘minor’, using the criteria of point 21L.A.63.

Wherever there is doubt as to the classification of a change, EASA should be consulted for clarification.

When the strict application of the point (c)(4) criteria results in a major classification, the declarant may request reclassification by EASA.

A simple design change planned to be mandated by an airworthiness directive may be reclassified as minor due to the involvement of EASA in the continued airworthiness process when this is agreed between EASA and the declarant.

The reasons for a classification decision should be recorded.

(4) General guidance on the classification of major changes

A change that is judged to have an ‘appreciable effect on the mass, balance, structural strength, reliability, declared noise or emissions levels, operational characteristics, or other characteristics affecting the airworthiness or the environmental compatibility’ is classified as major, in particular, but not only, when one or more of the following conditions are met:

(i) where the change requires an adjustment of the detailed technical specifications other than electing to comply with later certification specifications;

(ii) where the declarant proposes a new interpretation of the certification specifications used to define the applicable detailed technical specifications;

(iii) where the demonstration of compliance uses methods that have not been previously determined as appropriate for the nature of the change;

(iv) where the extent of new substantiation data necessary to comply with the applicable detailed technical specifications and the degree to which the original substantiation data has to be reassessed and re-evaluated is considerable;

(v) where the change alters the airworthiness limitations or the operating limitations;

(vi where the change is made mandatory by an airworthiness directive or the change is the terminating action of an airworthiness directive (ref. point 21L.A.4), see Note 1; and

(vii) where the design change introduces or affects functions where the failure effect is classified as ‘catastrophic’ or ‘hazardous’.

Note 1: A change previously classified as minor and approved prior to the decision to issue an airworthiness directive needs no reclassification. However, EASA retains the right to review the change and reclassify/reapprove it if found necessary.

Note 2: The conditions listed in points (i) through (vii) above are an explanation of the criteria noted in point 21L.A.63 as referenced by point 21L.A.103.

For an understanding of how to apply the above conditions, it is useful to take note of the examples given in Appendix A to GM 21L.A.103.

(5) Guidance on the classification of changes to aircraft flight manuals (AFMs)

The following changes to the AFM are deemed to be minor:

(i) revisions to the AFM associated with changes to the design that are classified as minor in accordance with point 21L.A.103;

(ii) revisions to the AFM that are not associated with changes to the design (also identified as stand-alone revisions) which fall into one of the following categories:

(A) changes to limitations or procedures that remain within already declared limits (e.g. weight, structural data, etc.);

(B) consolidation of two or more previously declared and compatible AFMs into one, or the compilation of different parts taken from previously declared and compatible AFMs that are directly applicable to the individual aircraft (customisation); and

(C) the introduction into a given AFM of compatible and previously declared AFM amendments, revisions, appendices or supplements; and

(iii) administrative revisions to the AFM, defined as follows:

(A)

(a) editorial revisions or corrections to the AFM;

(b) conversions of previously Federal Aviation Administration (FAA)- or EASA-approved combinations of units of measurement added to the AFM in a previously approved manner;

(c) the addition of aircraft serial numbers to an existing AFM where the aircraft configuration, as related to the AFM, is identical to the configuration of aircraft already covered by that AFM;

(d) the removal of references to aircraft serial numbers no longer applicable to that AFM; and

(e) the translation of an AFM into the official language of the State of design or State of registry.

(6) Guidance on the classification of changes to declared aircraft noise levels

(ii) All other changes to the declared aircraft noise levels are classified as major changes.

(iii) Examples of major changes are provided in Appendix A to GM1 21L.A.103.

Appendix A to GM1 21L.A.103 Classification of changes to the design of an aircraft for which design compliance has been declared

ED Decision 2023/013/R

EXAMPLES OF MAJOR CHANGES PER DISCIPLINE

The information below is intended to provide a few examples of major changes per discipline, resulting from the application of point 21L.A.103. It is not intended to present a comprehensive list of all major changes. Examples are categorised per discipline and are applicable to all products (aircraft, engines, propellers). However, a particular change may involve more than one discipline, e.g. a change to engine controls may be covered in engines and systems (software).

The persons that assess the change for its classification should always be aware of the interaction between disciplines and the consequences this will have when assessing the effects of a change (i.e. operations and structures, systems and structures, systems and systems, etc.).

Specific rules may exist which override the guidance of these examples.

In Part 21 Light, a negative definition is given of minor changes only. However, in the following list of examples, it was preferred to give examples of major changes.

Where in this list of examples the words ‘has effect’ or ‘affect(s)’ are used, they should always be understood as being the opposite of ‘no appreciable effect’ as in the definition of minor change in point 21L.A.63. Strictly speaking, the phrase ‘has appreciable effect’ and ‘appreciably affect(s)’ should have been used, but this has not been done to improve readability.

1. Structure

(i) Changes such as a change of dihedral, addition of floats.

(ii) Changes to materials, processes or methods of manufacture of primary structural elements, such as spars, frames and critical parts.

(iii) Changes that adversely affect fatigue or damage tolerance or life-limit characteristics.

(iv) Changes that adversely affect aeroelastic characteristics.

2. Cabin safety

(i) Changes which introduce a new cabin layout of sufficient change to require a reassessment of the emergency evacuation capability, or changes which adversely affect other aspects of passenger or crew safety.

Items to consider include but are not limited to:

— changes to or introduction of dynamically tested seats;

— changes to cabin layouts that affect evacuation path or access to exits;

— changes to the cabin area in striking distance of the occupant’s head or torso introducing potentially injurious objects.

3. Flight

Changes which adversely affect the approved performance or brake changes that affect braking performance.

Changes which adversely affect the flight envelope.

Changes which adversely affect the handling qualities of the product, including changes to the flight controls function (gains adjustments, functional modification to software), or changes to the flight protection or warning system.

4. Systems

For systems assessed under CS 23.2510, the classification process is based on the functional aspects of the change and its potential effects on safety.

(i) Where the failure effect is ‘catastrophic’ or ‘hazardous’, the change should be classified as ‘major’.

(ii) Where the failure effect is ‘major’, the change should be classified as ‘major’ if:

— aspects of the compliance demonstration will use a means that has not been previously utilised for the nature of the change to the system; or

— the change affects the pilot–system interface (displays, controls, approved procedures); or

— the change introduces new types of functions/systems such as GPS primary, TCAS, predictive windshear, HUD.

The assessment of the criteria for software changes to systems should also be performed.

When software is involved, account should be taken also of the following guidelines:

Where a change is made to software produced in accordance with the guidelines of the latest edition of AMC 20-115 (see AMC-20 document), the change should be classified as ‘major’ if either of the following applies, and the failure effect is ‘catastrophic’, ‘hazardous’ or ‘major’:

(i) the executable code for software, determined to be Level A or Level B in accordance with the guidelines, is changed unless that change involves only a variation of a parameter value within a range already verified for the previous certification standard; or

(ii) the software is upgraded to or downgraded from Level A, Level B or Level C; or

(iii) the executable code, determined to be level C, is deeply changed, e.g. after a software re-engineering process accompanying a change of processor.

For software developed to guidelines other than the latest edition of AMC 20‑115, the declarant should assess the changes in accordance with the foregoing principles.

For other codes the principles noted above may be used. However, due consideration should be given to specific certification specifications/interpretations.

5. Propellers

Changes to:

(i) diameter,

(ii) aerofoil,

(iii) planform,

(iv) material,

(v) blade retention system, etc.

6. Engines

Changes:

(i) that adversely affect operating speeds, temperatures, and other limitations;

(ii) that affect or introduce parts identified by CS E-510 where the failure effect has been shown to be ‘hazardous’;

(iii) that affect or introduce engine critical parts (CS E-515) or their life-limits;

(iv) to a structural part which requires a resubstantiation of the fatigue and static load determination used during the original compliance demonstration;

(v) to any part of the engine which adversely affects the existing containment capability of the structure;

(vi) that adversely affect the fuel, oil and air systems, which alter the method of operation, or require reinvestigation against the original detailed technical specifications;

(vii) that introduce new materials or processes, particularly on critical components.

7. Noise

The examples provided below are not exhaustive and will not, in every case, result in an appreciable effect on the declared noise levels and, therefore, will not per se and in every case result in a major change classification.

Examples of noise-related changes for aeroplanes that might lead to a major change classification are:

(i) a change that might affect the aircraft’s take-off performance including:

— a change to the maximum take-off mass;

— a change to the take-off distance;

— a change to the rate of climb; or

— a change to VY (best rate of climb speed);

(ii) a change that increases the aircraft’s drag (e.g. the installation of external cargo pods, external fuel tanks, larger tyres to a fixed undercarriage, floats etc.);

(iii) a change of engine or propeller type;

(iv) a change in take-off power including a change in engine speed (tachometer ‘red line’) or, for piston engines, a change to the manifold pressure limitations;

(v) a change to the highest power in the normal operating range (‘top of green arc’);

(vi) in the case of an aircraft where take-off power/engine speed is time limited, a change in the period over which take-off power/engine speed may be applied;

(vii) a change to the engine inlet or exhaust including, if fitted, the inlet or exhaust muffler;

(viii) a change in propeller diameter, tip shape, blade thickness or the number of blades;

(ix) the installation of a variable or adjustable pitch propeller in place of a fixed pitch propeller and vice versa;

(x) a change that causes a change to the angle at which air flows into the propeller.

8. Power plant installation

Changes which include:

(i) control system changes which affect the engine/propeller/airframe interface;

(ii) new instrumentation displaying operating limits;

(iii) modifications to the fuel system and tanks (number, size and configuration);

(iv) change of engine/propeller type.

9. Stand-alone changes to non-ALS ICAs that require additional work to demonstrate compliance with the applicable detailed technical specifications as follows:

(i) the introduction of novel technology for inspection purposes related to an ALS task;

(ii) changes that adversely affect the assumptions made during the original demonstration of compliance: e.g. some specific inspection procedures, such as inspection procedures for use after a hard landing, may include a decision-making chart based on the level of exceedance of the load in comparison with the limit loads; such criteria, and adverse changes, should be taken into consideration.

Declaration process

Appendix B to point 21L.A.103 Classification of changes to the design of an aircraft for which design compliance has been declared

ED Decision 2023/013/R

The following tables provide examples of ‘substantial’ changes. The classification may change due to cumulative effects and/or combinations of individual changes.

A.1 Examples of ‘substantial’ changes for small aeroplanes (CS‑23)

A.1.1 Table A‑1 contains examples of changes that are ‘substantial’ for small aeroplanes (CS‑23).

Table A-1 — Examples of when a new declaration of design compliance would be required under Subpart C for substantial changes for small aeroplanes (CS‑23)

|

Example |

Description of change |

Notes |

|

1. |

Change to wing location (tandem, forward, canard, high/low). |

Proposed change to the design is so extensive that a substantially complete demonstration of compliance with the applicable detailed technical specifications is required. |

|

2. |

Change to engine configuration (tractor/pusher). |

Proposed change to the design is so extensive that a substantially complete demonstration of compliance with the applicable detailed technical specifications is required. |

|

3. |

Change from an all-metal to all-composite aeroplane. |

Proposed change to the design is so extensive that a substantially complete demonstration of compliance with the applicable detailed technical specifications is required. |

Regulation (EU) 2022/1358

(a) A declarant who made a declaration of aircraft design compliance in accordance with Subpart C of this Annex may declare compliance of a minor change to the design of that aircraft under the conditions laid down in this Subpart. In addition, such a declaration of compliance may also be made, under the conditions laid down in this Subpart, by a design organisation approved in accordance with point (c)(3) of point 21.A.263 of Annex I (Part 21) .

(b) Only the declarant who made a declaration of aircraft design compliance in accordance with Subpart C of this Annex may declare the compliance of a major change to the design of an aircraft for which design compliance has been declared in accordance with Subpart C of this Annex, under the conditions laid down in this Subpart.

(c) By derogation from point (b) of point 21L.A.104, if the declarant who made a declaration of aircraft design compliance in accordance with Subpart C of this Annex is no longer active or is unresponsive to requests for design changes, the compliance of a changed aircraft design may also be declared in accordance with Subpart C of this Annex by a design organisation approved in accordance with point (c)(4) of point 21.A.263 of Annex I (Part 21) within the scope of their terms of approval, or by any other natural or legal person who is able to undertake the obligations laid down in point 21L.A.47 with respect to that changed aircraft.

21L.A.105 Declaration of design compliance for minor changes

Regulation (EU) 2022/1358

(a) Prior to installing or incorporating or agreeing with a production organisation to install or incorporate a minor change to the design of an aircraft for which design compliance has been declared in accordance with Subpart C of this Annex the organisation that has designed that minor change shall declare that the design of that minor change complies with:

1. either the detailed technical specifications incorporated by reference in the declaration of design compliance of the aircraft, unless those detailed technical specifications or parts of them are no longer applicable in accordance with point 21L.B.61 because the Agency has determined that experience from other similar products in service or products that have similar design features has shown that unsafe conditions may develop, and the detailed technical specifications that were referenced in the declaration of design compliance of the aircraft do not address this unsafe condition, or

2. the detailed technical specifications applicable, on the date on which the declaration is made in accordance with point 21L.B.61, if chosen by the declarant; and

3. the applicable environmental protection requirements referred to in point 21L.B.61 which are applicable on the date on which the declaration is made.

(b) The declaration of design compliance shall be made in a form and manner established by the Agency.

(c) The declarant or the organisation that has designed the minor change shall maintain a register of minor changes to the design of aircraft for which design compliance has been declared, and make any declaration made in accordance with point (a) available to the Agency upon request.

AMC1 21L.A.105(a) Declaration of design compliance for minor changes

ED Decision 2023/013/R

REQUIREMENTS FOR THE DECLARATION OF A MINOR CHANGE

(a) Applicability of point 21L.A.105

Point 21L.A.105 should be complied with by declarants for the declaration of compliance of a minor change, including design organisation approval (DOA) holders that declare compliance of minor changes under their privileges as per point (c)(3) of point 21.A.263 of Annex I (Part 21).

In accordance with point 21L.A.105(c) for declarations of compliance for minor changes, the substantiating data and the declaration of compliance required by point 21L.A.105(a) should be produced but does not need to be submitted to EASA. They should be, however, kept on record and made available to EASA upon request during any oversight visit.

(b) The declaration process

The declaration process comprises the following steps:

(1) classification of the change;

(2) applicable detailed technical specifications;

(3) determination of compliance;

(4) declaration of design compliance.

(c) Detailed technical specifications

The detailed technical specifications for a minor change consist of the detailed technical specifications that were incorporated by reference in the declaration of design compliance that was submitted for the particular aircraft under Subpart C unless EASA has determined that these are no longer appropriate, and the latest detailed technical specifications should be complied with or the declarant elects to comply with these detailed technical specifications.

(d) Determination of compliance required by point 21L.A.105(a)

The declarant should determine compliance with the applicable detailed technical specifications established for the minor change for all areas that are either physically changed or functionally affected by the minor change.

(1) Means of compliance: the declarant should define and record the means (calculation, test or analysis, etc.) by which compliance is determined. Appendix A to AMC1 21L.A.108(a) may be used for this purpose.

(2) Compliance documents: the compliance determination should be recorded in compliance documents. For minor changes, one comprehensive compliance document may be sufficient, provided that it contains evidence of all aspects for compliance. AMC1 21L.A.108(b) may also be used, where applicable.

(3) Aircraft manuals: where applicable, supplements to manuals (e.g. aircraft flight manual (AFM), aircraft maintenance manual (AMM), etc.) may be issued.

See also additional guidance below (point (e)) on embodiment/installation instructions.

(e) Embodiment/installation instructions

The instructions for the embodiment/installation of the change (e.g. service bulletin, modification bulletin, production work order, etc.) should be defined. This may include the installation procedure, the required material, etc.

AMC1 21L.A.105(b) Declaration of design compliance for minor changes

ED Decision 2023/013/R

FORM AND MANNER

The declarant should complete and file a declaration of compliance for the minor change using the form which can also be downloaded from the EASA website for the declaration of minor changes/minor repair designs.

If there are any changes to the data (e.g. propeller or engine designation) that was provided in the EASA Part 21 Light database of declared noise levels as a result of the minor change, then this data should be added by the declarant.

The justification of the classification of the change should also be recorded.

Declaration of design compliance for a Minor Change / Minor Repair Design

|

1. Designation |

|

|

Minor Change |

Minor Repair

|

|

|

|

|

Small Aeroplane with a MTOM of 1200Kg or less and a max seating configuration of 2 persons. |

Sailplane with a MTOM of 1200kg or less Powered Sailplane with a MTOM of 1200kg or less Balloon designed for no more than 4 persons Hot Airship designed for no more than 4 persons. |

||

|

2.2 Applicability |

|||

|

2.2.1 Design details |

Registered Declaration Number for the original product |

|

|

|

Original Declarant |

|

||

|

Type Name |

|

||

|

Model(s) |

|

||

|

2.3 Applicable technical specifications |

(if these are not the original technical specifications against which compliance was originally declared in accordance with Part 21 Light Subpart C due to the reasons stated in 21L.A.105 (a)(1) or (2) then this should be indicated here). |

||

|

3. Description |

|

|

3.1 Title |

|

|

3.2 Description |

|

|

3.3 Affected Areas (including manuals) |

|

|

3.4 Re-Investigations

|

|

|

4. Declarants’ declaration and acceptance of the General Conditions |

||

|

I declare that I have the legal capacity to make this declaration and that all information provided in this declaration is correct and complete. I hereby declare that the design of the minor change/repair described in Section 3 is in compliance with the applicable detailed technical specifications detailed in Section 2.3 and the applicable environmental protection requirements. I hereby declare that no features or characteristics have been identified that may make the aircraft after the minor change or repair has been incorporated unsafe or environmentally incompatible for the intended use. I hereby commit to undertake the obligations of a declarant of a declaration of design compliance as detailed in point 21L.A.106 of Annex Ib to Regulation (EU) 748/2012. I declare that I have provided the required information and that it is accurate and complete and indicated where it is not applicable. |

||

|

|

|

|

|

Date/Location |

Name |

Signature |

|

This Declaration should be retained by the declarant and made available upon request by EASA

|

||

AMC1 21L.A.105(c) Declaration of design compliance for minor changes

ED Decision 2023/013/R

REGISTER OF DECLARATIONS FOR MINOR CHANGES

The register that is used by the declarant to record the declarations of design compliance for minor changes should also comply with point 21L.A.7 and be easily accessible in case EASA requests the details of a specific minor change during oversight.

21L.A.106 Obligations of the person making a declaration of compliance of the design of a minor change

Regulation (EU) 2022/1358

Any person that has made a declaration of compliance of a minor change to an aircraft design in accordance with point 21L.A.105 shall:

(a) maintain a register of those declarations and shall make those declarations available to the Agency upon request;

(b) retain all supporting documents for a declaration of design compliance, and make them available to the Agency upon request;

(c) undertake all other obligations of a declarant of a declaration of design compliance set forth in Subpart A of this Annex.

21L.A.107 Declaration of design compliance for a major change

Regulation (EU) 2022/1358

(a) Prior to installing or incorporating or agreeing with a production organisation to install or incorporate a major change to the design of an aircraft for which design compliance has been declared in accordance with Subpart C of this Annex, the organisation that has designed that major change shall declare that the design of that major change and the areas affected by that change comply with:

1. either the detailed technical specifications incorporated by reference in the declaration of design compliance of the aircraft, unless those detailed technical specifications or parts of them are no longer applicable in accordance with point 21L.B.61 because the Agency has determined that experience from other similar products in service or products that have similar design features has shown that unsafe conditions may develop and the detailed technical specifications that were referenced in the declaration of design compliance of the aircraft do not address this unsafe condition, or

2. the detailed technical specifications applicable on the date on which the declaration is made in accordance with point 21L.B.61, if chosen by the declarant; and

3. the applicable environmental protection requirements referred to in point 21L.B.61 which are applicable on the date on which the declaration is made.

(b) The declaration of design compliance shall be made in a form and manner established by the Agency.

(c) The declaration shall contain at least the following information:

1. the name of the person submitting the declaration, and their address/place of business;

2. the declaration reference number of the aircraft to which the major change relates;

3. a unique reference for identifying the major change;

4. indication of the detailed technical specifications and the applicable environmental protection requirements with which the declarant declares compliance;

5. a signed statement made under the sole responsibility of the person making the declaration that the design of the major change is in compliance with the detailed technical specifications and the applicable environmental protection requirements referred to in point (4), according to the compliance demonstration plan referred to in point (d)(3);

6. a signed statement made under the sole responsibility of the person making the declaration that no features or characteristics have been identified by that person that may make the aircraft unsafe or environmentally incompatible for the intended use;

7. a signed commitment that the person making the declaration will undertake the obligations referred to in point 21L.A.47 in respect of the changed aircraft design;

8. the instructions for continued airworthiness;

9. the operating limitations, if changed;

10. the data sheet for airworthiness and, if applicable, the record of emissions compliance;

11. the data sheet for noise, if applicable;

12. any other conditions or limitations prescribed for the aircraft in the applicable detailed technical specifications and the applicable environmental protection requirements with which the declarant declares compliance.

(d) The declarant that designs a major change shall submit the declaration referred to in point (c) to the Agency. Together with this declaration, the declarant shall provide to the Agency:

1. a description of the major change;

2. basic data about the major change, including the operating characteristics, design features and any limitations;

3. a compliance demonstration plan detailing the means for compliance demonstration that was followed during the compliance demonstration;

4. recorded justifications of compliance within the compliance data obtained from the compliance activities that have been conducted according to the compliance demonstration plan;

5. the means by which such compliance with the applicable detailed technical specifications and applicable environmental protection requirements in point 21L.B.61 has been demonstrated;

6. where compliance is demonstrated by carrying out tests, recorded justification of the conformity of the test articles and equipment, demonstrating:

(i) for the test specimen, that:

(A) the materials and processes adequately conformed to the specifications for the design;

(B) the constituent parts of the products adequately conformed to the drawings in the design; and

(C) the manufacturing processes, construction and assembly adequately conformed to those specified in the design;

(ii) that the test and measuring equipment used for the test were adequate for the test and appropriately calibrated;

7. reports, results of inspections or tests that the declarant found necessary to determine that the aircraft complies with the applicable detailed technical specifications and applicable environmental protection requirements.

(e) The declaration of a major change to a declaration of design compliance shall be limited to the specific configuration(s) in the declaration of design compliance to which the change relates.

AMC1 21L.A.107(b) Declaration of design compliance for a major change

ED Decision 2023/013/R

FORM AND MANNER

The request for registration should be completed along with the declaration of design compliance and sent to EASA by email or regular mail following the information provided on the EASA website88 https://www.easa.europa.eu/document-library/application-forms/certifica… (accessed: 20 October 2023)..

If the data sheet for airworthiness needs to be adapted, then an amended version should also be provided.

If there are any changes to the data that was provided in the EASA Part 21 Light database of declared noise levels as a result of the major change, then this data should be added by the declarant as a new record within the EASA Part 21 Light database identifying that it is applicable after the major change.

|

1. Identification of Activity |

|

|

Major Change |

Major Repair |

|

2. Product Identification |

||

|

2.1 Applicability |

Declared Type Name (this must be a unique means to identify the aircraft) |

|

|

Declared Model Name(s) |

|

|

|

Original Declarant |

|

|

|

Registered Declaration No |

|

|

|

2.2 Product Category |

Small Aeroplane with a MTOW of 1 200 kg or less and a max. seating configuration of 2 persons Sailplane with a MTOW of 1 200 kg or less Powered Sailplane with a MTOW of 1 200 kg or less Balloon designed for no more than 4 persons Hot Air Airship designed for no more than 4 persons |

|

|

2.3 Technical Specifications |

(if these are not the original technical specifications against which compliance was originally declared in accordance with Part 21 Light Subpart C due to the reasons stated in 21L.A.107 (a)(1) or (2) then this should be indicated here). |

|

|

2.4 Environmental Protection Requirements (if applicable) |

||

|

3. Description |

|

|

3.1 Title |

|

|

3.2 Description |

|

|

3.3 Affected Areas including manuals |

|

|

3.4 Re-Investigations |

Compliance Demonstration Plan – doc. Ref.: (Please provide the reference of the Compliance Demonstration Plan required by 21L.A.107(d)(3) or 21L.A.226(d)(3), respectively)

Documentation, if changed, to submit with the Declaration in accordance 21L.A.107(c): • Airworthiness Data Sheet • Aircraft Flight Manual including any limitations • Instructions for Continued Airworthiness • Any other conditions/limitations which the declarant wishes to declare • EASA Noise Record Number |

|

4. Declarant’s Statement |

||

|

4.1. Declaration of Compliance |

||

|

I declare that I have the legal capacity to submit this Declaration to EASA and that all information provided in this Declaration form is correct and complete. I hereby declare that the design of the major change/repair described in Section 3 is in compliance with the applicable detailed technical specifications detailed in Section 2.3 and the applicable environmental protection requirements (if applicable) in Section 2.4 in accordance with the compliance demonstration plan detailed in Section 3.4. I hereby declare that no features or characteristics have been identified that, after the major change or repair has been incorporated, may make the aircraft unsafe or environmentally incompatible for the intended use. I hereby commit to undertake the obligations of a Declarant of a Declaration of Design Compliance as detailed in point 21L.A.47 and for major repairs (if applicable) point 21L.A.228 of Annex Ib to Regulation (EU) 748/2012. I declare that I have provided the required information in 3.4 and that it is accurate and complete and indicated where it is not applicable. |

||

|

|

|

|

|

Date/Location |

Name |

Signature |

|

Important Note: EASA cannot accept Declarations without signature. Please make sure that you sign the Declaration. |

||

|

This declaration should be sent by email to: applicant.services [at] easa.europa.eu (applicant[dot]services[at]easa[dot]europa[dot]eu) |

||

GM1 21L.A.107(c) Declaration of design compliance for a major change

ED Decision 2023/013/R

INFORMATION TO BE PROVIDED TO EASA

The documents and information that are required to be provided to EASA under point 21L.A.107(c) may be provided to EASA by the declarant in advance of the submission of the declaration of design compliance for the major change. This would be advantageous for the declarant to facilitate EASA’s investigations and to determine the need for the first-article inspection under point 21L.B.121(b).

AMC1 21L.A.107(e) Declaration of design compliance for a major change

ED Decision 2023/013/R

SPECIFIC CONFIGURATION(S)

The compliance-demonstration process always takes into account the specific configuration(s) in the declaration of design compliance to which the major change relates. This (these) configuration(s) may be defined by product models/variants or by design changes to the declaration. The demonstration of compliance applies to this (these) applicable specific configuration(s). Consequently, the declaration of the major change excludes any other configurations, in particular those that already exist but are not considered in the compliance-demonstration process, as well as those that may be declared in the future.

21L.A.108 Compliance activities for declaring compliance of a major change

Regulation (EU) 2022/1358

Prior to making a declaration of compliance in accordance with point 21L.A.107, the declarant shall, for that specific design:

(a) establish a compliance demonstration plan detailing the means for compliance demonstration that shall be followed during the compliance demonstration. This document shall be updated as necessary;

(b) record the justification of compliance within compliance documents according to the compliance demonstration plan;

(c) perform testing and inspections as necessary in accordance with the compliance demonstration plan;

(d) ensure and record the conformity of the test articles and equipment and ensure that the test specimen conforms to the specifications, drawings, manufacturing processes, construction and assembly means in the design;

(e) ensure that the test and measuring equipment to be used for testing are adequate for testing and appropriately calibrated;

(f) allow the Agency to conduct or participate in any inspections or tests of aircraft in the final or suitably mature design and production configuration that are necessary to determine that the changed product has no feature or characteristic that makes the aircraft unsafe or environmentally incompatible for the intended use;

(g) carry out flight testing, in accordance with the methods for such flight testing specified by the Agency, as necessary to determine that the aircraft complies with the applicable detailed technical specifications and the applicable environmental protection requirements.

GM1 21L.A.108 Compliance activities for declaring compliance of a major change

ED Decision 2023/013/R

VOLUNTARY INVOLVEMENT OF EASA PRIOR TO THE SUBMISSION OF DECLARATION

The declarant may choose to involve EASA prior to submitting the declaration of design compliance for a major change. This would allow EASA to:

(f) check the scope of the product is still within the scope of Subpart C;

(g) provide guidance on the completeness of the compliance-demonstration plan and the selection of means of compliance;

(h) advise on the selection of the applicable detailed technical specifications and applicable noise requirements;

(i) provide guidance about noise tests (if applicable) and witness them;

(j) avoid any issues or delays during the the physical inspection and assessment of the aircraft (if considered necessary prior to issuing flight conditions under point 21L.B.242(a)4) or if considered to be necessary under point 21L.B.121(b)).

The initiation of the project may occur before starting the compliance activities or during those activities. The assignment of a dedicated project number would facilitate any subsequent communication with EASA. This will facilitate the provision of compliance documentation required by point 21L.A.107(d), which may be provided by the declarant to EASA at key stages in the compliance demonstration prior to the submission of the declaration of design compliance for the major change.

AMC1 21L.A.108(a) Compliance activities for declaring compliance of a major change

ED Decision 2023/013/R

COMPLIANCE-DEMONSTRATION PLAN FOR A MAJOR CHANGE

The compliance-demonstration plan for a major change is a document that allows the declarant to manage and control the design of the major change, as well as the process of compliance demonstration, and that enables EASA to investigate the root cause(s) in the event of a safety issue being discovered.

The description of the change should include an explanation of the purpose of the change, the pre-modification and post-modification configuration(s) of the aircraft, schematics/pictures, and any other detailed features and boundaries of the physical change (this may be supplemented by drawings or outlines of the design, if this helps to understand the design change), as well as the identification of the changes in areas of the aircraft that are functionally affected by the change, and the identification of any changes to the approved manuals.

The items of the declaration of aircraft design compliance made in accordance with Subpart C that are affected by the change and for which a new demonstration of compliance is necessary should be identified together with the means (e.g. calculation, test or analysis) by which it is proposed to demonstrate compliance.

The compliance demonstration should include the analysis for the classification of the change in accordance with GM1 21L.A.103.

In particular, the following information should typically be expected:

— identification of the relevant personnel that make decisions affecting airworthiness and environmental compatibility, and that will interface with EASA during any physical inspection and assessment of the changed product if required under point 21L.B.121(b);

— subcontracting arrangements for design, environmental compatibility and/or production (if applicable).

Point 21L.A.107(d)(1) ‘Description of the major change’

An overview of the:

— architecture, functions, systems;

— dimensions, design weights, payloads, design speeds;

— engines and power/thrust rating;

— materials and technologies;

— cabin configuration aspects;

— options (e.g. weight variants, power/thrust rating variants, optional avionics equipment items, brake options, tyre options, floats, skids).

Point 21L.A.107(d)(2) ‘Operating characteristics, design features and limitations’

— operating speed limitations;

— service ceiling, maximum airfield elevation;

— cabin pressure;

— limit load factors;

— number of passengers, minimum crew, payload, range;

— weight and centre-of-gravity (CG) envelope and fuel loading;

— performance;

— environmental envelope;

— runway surface conditions;

— other items, if considered to be more appropriate, which address the specific aeronautical product.

The declarant should provide detailed information about the means of compliance with the applicable requirements identified under point 21L.A.107(a). This should include the following:

— a compliance checklist addressing each requirement, the proposed means of compliance (see Appendix A to AMC1 21L.A.107(a) below for the relevant codes), and the related compliance document(s);

— identification of industry standards, methodology documents, handbooks and any other acceptable means of compliance, specified in the airworthiness or noise data sheet, which have been followed in the demonstration of compliance;

— when the compliance demonstration involves testing, a description of the ground- and flight-test article(s), test method(s), test location(s), test schedule, test house(s), test conditions (e.g. limit load, ultimate load), as well as of the intent/objective(s) of the testing; and

— when the compliance demonstration involves analyses/calculations, a description/ identification of the tools (e.g. name and version/release of the software programs) and methods used, the associated assumptions, limitations and/or conditions, as well as of the intended use and purpose.

For every aspect mentioned above, the declarant should clearly identify whether the demonstration of compliance involves different means than those contained in the published AMC to the relevant CSs and any method (analysis or test) which is novel or unusual for the declarant.

For every aspect related to compliance with the applicable environmental protection requirements mentioned above, the declarant should clearly identify whether the demonstration of compliance involves means that are described in ICAO Doc 9501 ‘Environmental Technical Manual’.

Appendix A to AMC1 21L.A.108(a) Compliance activities for declaring compliance of a major change

ED Decision 2023/013/R

MEANS-OF-COMPLIANCE CODES

|

Type of compliance |

Means of compliance |

Associated compliance documents |

|

Engineering evaluation |

MC0: (a) compliance statement (b) reference to design data (c) election of methods, factors, etc. (d) definitions |

(a) Design data (b) Recorded statements |

|

MC1: design review

|

(c) Descriptions (d) Drawings |

|

|

MC2: calculation/analysis |

(e) Substantiation reports |

|

|

MC3: safety assessment |

(f) Safety analyses |

|

|

Tests |

MC4: laboratory tests |

(g) Test programmes (h) Test reports (i) Test interpretations |

|

MC5: ground tests on related product(s) |

||

|

MC6: flight tests |

||

|

MC8: simulation |

||

|

Inspection |

MC7: design inspection/audit |

(j) Inspection or audit reports |

|

Equipment qualification |

MC9: equipment qualification |

Note: Equipment qualification is a process that may include all previous means of compliance at equipment level. |

AMC1 21L.A.108(b) Compliance activities for declaring compliance of a major change

ED Decision 2023/013/R

COMPLIANCE DOCUMENTATION

(a) Compliance documentation comprises one or more test or inspection programmes/plans, reports, drawings, design data, specifications, calculations, analyses, etc., and provides a record of the means by which compliance with the applicable detailed technical specifications and environmental protection requirements has been demonstrated.

(b) Each compliance document should typically contain:

— the reference of the detailed technical specifications or environmental protection requirements addressed by the document;

— substantiation data demonstrating compliance (except test or inspection programmes/plans);

— a statement by the declarant declaring that the document provides the proof of compliance for which it has been created; and

— the declarant’s signature.

(c) Each compliance document should be unequivocally identified by its reference and issue date. The various issues of a document should be controlled and comply with point 21L.A.7.

AMC1 21L.A.108(c);(d);(e) Compliance activities for declaring compliance of a major change

ED Decision 2023/013/R

INSPECTIONS AND TESTS

In accordance with point 21L.A.108(d), the declarant must address the conformity of the test specimen, as well as of the test and measuring equipment.

Conformity of the test specimen

The recorded justification of the conformity of the test articles is intended to ensure that the manufactured test specimen adequately represents the declared applicable design data. Possible types of non-conformity may be the following:

— Non-conformity between the design of the test specimen and the originally intended design data at the time of the test. These are typically identified in the early stage of the test planning, and should be addressed as early as possible (e.g. in the test plan). There may be several reasons for such a non-conformity: to account for interfaces with the test equipment, to conservatively cover several or future design configurations, etc.

— Non-conformity between the manufactured test specimen and the design of the test specimen. Such a non-conformity may be the result of the manufacturing of the test specimen.

While it is convenient to define any possible non-conformity as early as possible, the declarant does not need to make the distinction between the two types of non-conformity above as long as they are explicitly addressed and justified by cross reference to the test plan or other documents. However, testing for the demonstration compliance with the applicable environmental protection requirements should be conducted with the final design of the product having incorporated the change.

Compliance demonstration is typically an iterative process in which the design is under continuous evolution. If the aircraft design evolves after the time of the inspection or test, then the final major change design should be checked against the originally intended design (as it was at the time of the inspection or test), and the differences (if any) should be analysed to ensure that the inspection or test results are representative of the final configuration. However, such changes made to the design may lead to the invalidation of the inspection or test results and the need to repeat the inspection or test. It is recommended that the declarant should have a thorough configuration management process to track the evolving design of the major change.

Conformity of the test and measuring equipment: the configuration of the test and measuring equipment should be defined in the test plan and include the following:

— definition/design of the test equipment (relevant tools, mechanical parts, electronic components used to execute the test); and

— definition of the measuring equipment:

— type/model of sensors, together with their technical characteristics;

— position and orientation of exciters and sensors; and

— electronic measuring equipment (in some cases, this may also include the acquisition and post-processing of data).

The configuration of the test and measuring equipment should be defined and controlled through test plans and supporting documentation. The test plan should also include the following elements:

— the test cases, methods, and procedures for test execution;

— the pass–fail criteria; and

— pre-, during- and post-test inspections.

The declarant should confirm that the test and measuring equipment conforms to its definition in the test plan, and that the sensors and measuring system are appropriately calibrated. Any non-conformity should be assessed, and it should be justified that it will not compromise the test purpose and results. This may be done either in the recorded justification of the conformity of the test articles and equipment or by cross reference to other documents (test minutes of meetings, test notes, etc.).

Use of the term ‘adequate’: the test and measuring equipment is considered ‘adequate’ as long as the test execution on the manufactured test specimen (including any non-conformity) and the use of the installed test set-up do not compromise the test purpose and results (for example, by providing better performance than the proposed type design, or by masking any potential failure mode or behaviour).

Changes that affect the validity of the recorded justification of the conformity of the test articles and equipment: if changes need to be introduced to the test specimen or to the test and measurement equipment after the justification has been recorded (and before the test is undertaken), then it must be updated.

Development versus compliance-demonstration tests: sometimes, tests of specimens that conform to a preliminary design, but are not intended for demonstration of compliance (known as development tests), are performed as part of a risk control strategy and to develop knowledge of a subject. Problems and failures found during development are part of the process of increasing the understanding of the design, including its failure modes and the potential for optimisation. Such development tests do not need to meet the requirements of point 21L.A.108(d) and (e).

Any planned test event should be classified in advance as either a development test or a compliance-demonstration test.

It is acceptable for a development test to finally form part of the compliance demonstration, and it may be declared afterwards to be a compliance-demonstration test as long as it meets the requirements of point 21L.A.108(d) and (e). For this reason, it is important to keep the configuration of such tests under control.

If the test specimen used for a compliance-demonstration test has already undergone a series of previous tests that may affect or ultimately invalidate its validity due to potential non-conformity to 21L.A.108(d) as required by point 21L.A.107(d)(6), this aspect should be considered when justifying the conformity, and specific analyses or inspections may be required to support such a statement.

Because of the above aspects, declarants may wish to inform EASA if they intend to conduct a campaign of development tests that may eventually be used as demonstration-of-compliance tests to establish whether EASA would wish to witness the tests.

AMC1 21L.A.108(f) Compliance activities for declaring compliance of a major change

ED Decision 2023/013/R

PHYSICAL INSPECTION OF THE FIRST ARTICLE

The declarant should be prepared for any additional investigations as notified by EASA according to point 21L.B.121(b).

Refer to AMC 21L.A.47(a) for an explanation of the activities performed under the first-article inspection.

GM1 21L.A.108(f) Compliance activities for declaring compliance of a major change

ED Decision 2023/013/R

INSPECTIONS AND TESTS PERFORMED BY EASA

The declarant should inform EASA sufficiently in advance about the execution of significant inspections and tests that are used for compliance-demonstration purposes in order to permit EASA the opportunity to perform or witness these inspections or tests in advance of any physical inspection and assessment of the changed product if required by point 21L.B.121(b).

This would be advantageous for the declarant to avoid any issues or delays if a physical inspection and assessment of the changed product is required (see point 21L.B.121(b)).

Additionally, the declarant may propose to EASA to perform or witness flight or other tests of particular aspects of the product during its development and before the design of the major change is fully defined. However, before EASA performs or witnesses any flight test, the declarant should perform these tests and should ensure that no features of the product preclude the safe conduct of the evaluation requested.

A recorded justification of the conformity of the test articles and equipment as per point 21L.A.107(d)(6) is required for the above tests.